KLIXON Aircraft Circuit Breakers15 Essential Facts

Introduction

Aircraft electrical systems represent complex networks of interconnected components operating under demanding conditions. Circuit breakers serve as critical safety devices within these networks, performing three essential functions:

- System Isolation: Enabling maintenance crews to isolate specific circuits for troubleshooting and repairs

- Load Management: Facilitating proper distribution and control of electrical power across aircraft systems

- Overcurrent Protection: Preventing damage to electrical systems and components by interrupting excessive current flow

Modern aircraft typically contain hundreds of circuit breakers, each protecting specific systems ranging from critical flight controls to auxiliary equipment. Their proper functioning directly impacts:

- Aircraft availability by preventing system damage

- Flight safety through the protection of essential systems

- Maintenance efficiency through accurate fault isolation

- Operational reliability via consistent electrical system performance

Table of Contents

What are Aircraft Circuit Breakers?

Aircraft circuit breakers are electro-mechanical protection devices engineered to specifications defined by aerospace standards AS58091 and MIL-C-5809. They operate as resettable circuit protection mechanisms that interrupt current flow when electrical parameters exceed predetermined thresholds. Their core functionality involves:

Functional Characteristics

- Reset Capability: Manual or remote reset functionality

- Status Indication: Visual position indicators for trip condition monitoring

- Trip Mechanism: Utilizes calibrated bimetallic elements or hybrid thermal-magnetic systems

- Environmental Resistance: Sealed construction for altitude, humidity, and contamination protection

Technical Parameters

- Nominal current rating: 0.5A to 100A

- Operating voltage: 28VDC/115VAC (400Hz)

- Temperature range: -55°C to +125°C

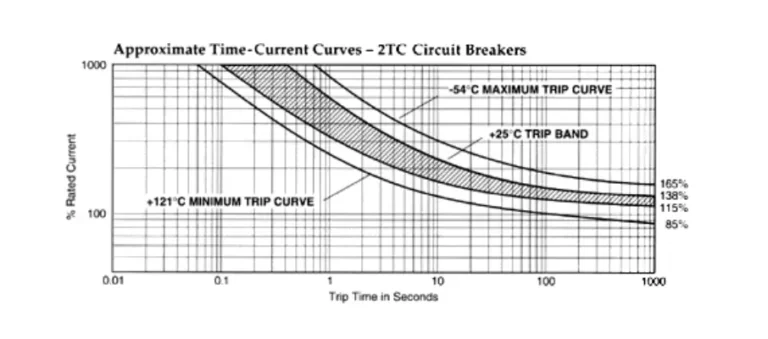

- Trip response time: Inverse time-current characteristic

KLIXON aircraft circuit breakers are thermal-mechanical protection devices specifically engineered for aerospace applications. These circuit breakers utilize a precisely calibrated bimetallic disc that responds to both electrical current and ambient temperature changes, providing reliable circuit protection against overcurrent conditions while maintaining circuit integrity under normal operating conditions.

Types of KLIXON Aircraft Circuit Breakers

These advanced circuit breakers incorporate temperature compensation mechanisms that adjust their trip points based on ambient temperature variations, ensuring consistent protection across diverse operating environments. They’re particularly crucial for aircraft operating in extreme temperature conditions, from high-altitude cold to ground-level heat.

These circuit breakers operate without temperature compensation mechanisms, making them suitable for applications where ambient temperature variations are less critical. They offer reliable protection while maintaining a simpler internal structure, potentially reducing maintenance requirements.

These fundamental protection devices utilize basic thermal trip mechanisms, offering essential circuit protection while maintaining cost-effectiveness. They’re often used in less critical aircraft systems where temperature compensation isn’t necessary.

KLIXON Aircraft Circuit Breakers Working Principles

Temperature Compensated Models

- Utilizes a dual-metal strip system

- Primary bimetallic element responds to current flow

- The trip point remains consistent across -55°C to +125°C

- The secondary compensation element adjusts for ambient temperature

Non-Temperature Compensated Models

- Single bimetallic strip design

- Simplified internal mechanism

- Direct current-to-heat conversion

- Trip point varies with ambient temperature

Thermal Circuit Breakers

- Standard trip curve characteristics

- Reset capability after the cooling period

- Basic thermal-mechanical operation

- Current-induced heating triggers the mechanism

KLIXON Aircraft Circuit Breakers: Key Features

Temperature Compensated

- Vibration resistance

- Extended service life

- MIL-STD-810 compliance

- Enhanced reliability in extreme conditions

- Precise trip points across the temperature range

Non-Temperature Compensated

- Robust construction

- Quick reset capability

- Cost-effective protection

- Standard mounting options

- Simplified maintenance requirements

Thermal Circuit Breakers

- Easy installation

- Economical solution

- Visual trip indication

- Manual reset function

- Basic overcurrent protection

KLIXON Aircraft Circuit Breakers: Competitive Advantages

Superior Reliability

- 99.9% reliability rate

- Industry-leading quality control

- Extensive testing documentation

- Certified for aerospace applications

Advanced Materials

- Reduced weight

- Enhanced durability

- Superior heat dissipation

- Aerospace-grade materials

Certification Compliance

- FAA approved

- EASA certified

- Military specification compliance

- International standards adherence

KLIXON Aircraft Circuit Breakers: Lifecycle Management and Replacement Guidelines

Replacement Criteria

- Age exceeds 10 years in service

- Visual inspection reveals wear or damage

- Trip characteristics drift beyond tolerance

- Operational cycles exceed manufacturer specifications

Mean Time Between Failures (MTBF)

- Thermal: 50,000+ hours

- Temperature Compensated: 100,000+ hours

- Non-Temperature Compensated: 75,000+ hours

Preventive Maintenance Schedule

- Visual inspection: Every 1000 flight hours

- Functional testing: Annual

- Complete replacement: Based on condition monitoring

Need Deeper Technical Specs? Contact our Engineering Team

KLIXON Aircraft Circuit Breakers: Applications

Critical Systems

- Navigation systems

- Primary flight controls

- Emergency power systems

- Communication equipment

Environmental Factors

- Vibration exposure

- Humidity resistance

- Temperature extremes

- Altitude considerations

KLIXON Aircraft Circuit Breakers: Conclusion

KLIXON aircraft circuit breakers represent essential safety components in modern aviation. Their reliable operation, diverse range of options, and robust construction make them indispensable for aircraft electrical system protection. While each type offers specific advantages, the selection should be based on application requirements, environmental conditions, and safety considerations.

The temperature-compensated variants provide the highest level of protection and reliability, particularly crucial for critical systems and extreme operating conditions. Non-temperature compensated and thermal options offer cost-effective solutions for less demanding applications while maintaining necessary safety standards.

Regular maintenance, proper installation, and adherence to replacement guidelines ensure optimal performance and safety throughout the circuit breaker’s operational life. As aviation technology continues to advance, KLIXON circuit breakers evolve to meet increasingly demanding requirements while maintaining their fundamental role in aircraft safety systems.

Looking for aSolution?

Our Technical Experts are Here to Bring your VISION to Life. Let’s DISCUSS How Our SOLUTIONS Can Maximize the VALUE of your PROJECT

Technical References

Industry Standards and Specifications

- AS58091: Aerospace Standard for Circuit Breakers

- MIL-C-5809: Military Specification for Circuit Breakers

- SAE AS8019: Circuit Breaker – Thermal, Aircraft

- RTCA/DO-160G: Environmental Conditions and Test Procedures for Airborne Equipment

- FAA Advisory Circular AC 43.13-1B: Acceptable Methods, Techniques, and Practices – Aircraft Inspection and Repair

Technical Publications

- ARINC Report 442-6: Circuit Breaker Specification

- Aviation Maintenance Technician Handbook – General (FAA-H-8083-30A)

- Aircraft Electrical and Electronic Systems: Principles, Operations, and Maintenance (Eismin, T.K., 2023)

- Aircraft Systems: Mechanical, Electrical, and Avionics Subsystems Integration (Moir, I., Seabridge, A., 2022)

Manufacturer Documentation

Sensata Technologies (KLIXON) technical documents:

- Installation Manuals

- Maintenance Requirements

- Product Specification Sheets

Regulatory Guidelines

- Transport Canada Airworthiness Manual Chapter 525

- EASA CS-25: Certification Specifications for Large Airplanes

- FAR Part 25: Airworthiness Standards: Transport Category Airplanes

Research Papers

- “Advanced Protection Mechanisms in Aircraft Electrical Systems” (Journal of Aerospace Engineering, 2024)

- “Reliability Assessment of Temperature-Compensated Circuit Breakers in Aviation Applications” (SAE Technical Paper Series, 2022)

- “Thermal Analysis of Aircraft Circuit Breakers Under Various Environmental Conditions” (IEEE Transactions on Aerospace Systems, 2023)