GIGAVAC DC Contactors5 Advanced Features

DC contactors are sophisticated electrical switches engineered to manage direct current (DC) power transmission in electrical systems. These precision devices act as critical control points, enabling or interrupting electrical circuits for various applications, including motor control, industrial machinery, renewable energy systems, and electrical equipment management. Unlike alternating current (AC) contactors, DC contactors are specifically optimized to handle the unique electrical characteristics of direct current, providing reliable and efficient power regulation in DC power networks.

Table of Contents

What are DC Contactors?

The DC contactor is an electromechanical switching device specifically engineered to control the flow of electrical current in direct current (DC) circuits by opening and closing internal contacts. As a result, providing critical switching capabilities for various applications across low to moderate voltage ranges. As well as, offering minimal electrical arcing during circuit transitions, ensuring reliable and controlled power management in industrial, automotive, renewable energy, and electronic systems.

The fundamental operation of the DC Contactors relies on an electromagnetic coil that generates a magnetic field to mechanically actuate electrical contacts, allowing precise and instantaneous current interruption or connection with optimal energy efficiency.

Breaking Down the Structural Elements of DC Contactors

The structure of DC contactors represents an advanced electromechanical design engineered to provide precise electrical switching capabilities. At its core, the technical configuration of the DC Contactors is almost similar to AC Contactors. DC Contactors are mainly constructed with an Electromagnetic system, contact mechanism, and Arc control system. Generally, DC Contactors consist of:

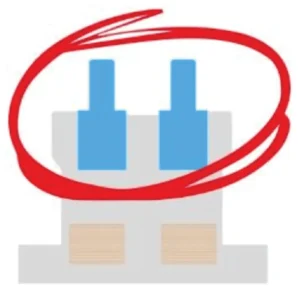

1. Electromagnetic Mechanism

Generates the magnetic field responsible for actuating the contactor’s switching mechanism, converting electrical energy into mechanical motion with high precision and efficiency. The electromagnetic coil mechanism of the DC contactor consists of a copper wire coil wound around an iron core, an armature, and a flapping structure with edge and angle rotation which is mainly adopted.

The magnetic field will be generated due to the flow of applied current to the wire coil. While the wire coil is connected to the direct current, there will be no Foucault’s current in the iron core during normal operation; for this reason, the iron core does not generate heat and there will be no iron loss. The force of the magnetic field depends on many factors such as the number of turns of the wire coil, the current that flows through the wire coil, and the material of the iron core.

To dissipate the coil properly, it is usually wound into a thin cylinder; for this reason, the wire coil can operate in a wide range of voltages from a few up to a thousand volts depending on the used application. In simple words, the electromagnetic wire coil is the driving force behind the operation of the DC Contactor by converting the electrical energy into magnetic energy, which is used to move the contactor’s mechanical parts, specifically the armature.

However, since the magnetic flux in the iron core is constant, having a short-circuit ring on the pole face of the iron core is not required; moreover, it is recommended to set a non-magnetic divider between the iron core and the armature to reduce the impact on residual magnetic resistance which will ensure the reliable release of the armature.

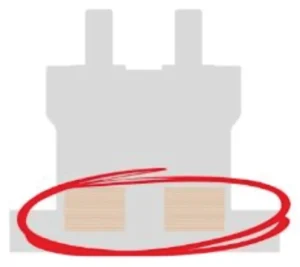

2. Contacts System

The contact forms the iron core of the DC Contactors which is the conductive component that withstands repeated electrical switching. The contact acts by enabling and/or interrupting the circuit connection under varying electrical load conditions. Furthermore, there are two typical types of contacts as the following:

- The main Contacts: are unipolar or bipolar (single pole or double pole) that handle the primary load current. The main contact is made to carry large amounts of current without overheating or deteriorating thanks to the used materials which are usually a combination of metals, such as silver alloys, which offer low resistance and high durability.

- Auxiliary Contacts: are considered secondary contacts that operate side-by-side with the main contacts. They are used in control circuits to provide feedback, signal, or control other devices. Besides that, auxiliary contacts carry much lower currents than the main contacts.

The quality of the contact material and design is considered a critical point because they must withstand the stress of switching high currents where arcing can be a serious challenge.

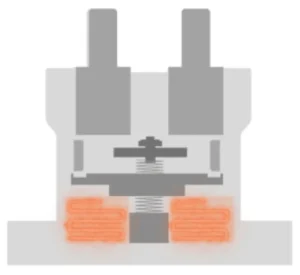

3. Arc Control Technique

What is an Electrical Arc?

The electrical arc is a discharge of electrical current where current flows across an ionized gas, vapor, or air gap between two electrodes. This conductive plasma pathway forms under specific voltage conditions, expending a relatively low voltage across the conductors. That is why the electrical arc is considered a critical challenge for DC Contactors, especially in high-voltage applications.

What is Arc Control Technologies

Modern circuit protection systems employ sophisticated arc chute assemblies to manage and extinguish electrical arcs effectively. These specialized components incorporate:

Arc Chute Design Elements

The primary arc control mechanism consists of multiple metallic plates arranged in a carefully engineered configuration. These plates serve to:

- Segment the primary arc into multiple smaller arcs

- Increase the effective arc path length

- Facilitate rapid thermal energy dissipation

Enhanced Arc Extinction Methods

State-of-the-art circuit breaker designs often integrate complementary arc control technologies, including:

- Electromagnetic arc driving systems

- Forced air cooling mechanisms

- Advanced ceramic arc-resistant materials

This comprehensive approach to arc management significantly enhances system reliability and extends equipment service life.

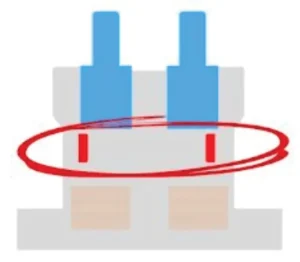

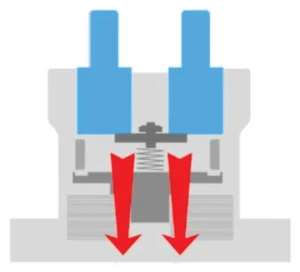

4. Armature Mechanism

This critical mechanical element translates electromagnetic force into precise contact movement using the contactor’s iron component. The energized electromagnetic wire coil generates a magnetic field that attracts the armature. This is the principle of opening and closing the DC Contactor’s contacts.

The armature is typically spring configured, which means it returns to the original position when the coil is de-energized. The mechanism of the armature must be harmonized and precise to ensure reliable and consistent electrical switching performance.

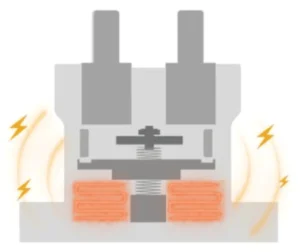

5. Spring Mechanism

Delivers consistent mechanical tension, facilitating contact reset when the wire coil is energized/de-energized, and maintaining optimal electrical contact pressure throughout the contactor’s operational lifecycle.

The spring’s design parameters require advanced engineering to achieve optimal force equilibrium: sufficient tension to ensure dependable mechanical operation, while maintaining a force threshold that permits efficient armature actuation when electromagnetic force is applied to the energized coil.

Additional advanced design features may include integrated arc suppression technologies, such as magnetic blow-out coils or arc chutes, which minimize electrical arcing and enhance overall switching reliability across diverse electrical applications.

6. Insulating Housing

Constructed from high-performance dielectric materials such as composite materials that are made to withstand mechanical shocks, vibrations, and environmental conditions like moisture and dust. The housing provides electrical isolation, mechanical protection, and thermal management for internal components.

7. Inert Gas Technology in Hermetically Sealed DC Contactors: Advanced Design Features

Advanced DC contactor systems implement hermetically sealed chambers filled with inert gases—primarily nitrogen or sulfur hexafluoride (SF6) to optimize operational integrity. This advanced containment methodology serves dual functions: preventing contact surface degradation through oxidation while simultaneously enhancing arc suppression capabilities.

Key Performance Benefits

- Contact surface longevity

- System reliability

- Operational safety in hazardous environments

- Maintenance intervals

- Overall service life expectancy

DC Contactors Operation: Working Principles

1. Initial Control Voltage

The operational cycle initiates when a specified control voltage energizes the electromagnetic wire coil system. This activation voltage should exactly match the coil specifications and may originate from either manual switching mechanisms (control circuit) or automated control architectures (relay or control system).

2. Electromagnetic Field Generation

Upon the applied control voltage, current flow through the coil generates a concentrated magnetic field. The engineered core structure optimizes magnetic flux density, producing sufficient attractive force for the armature.

3. Mechanical Armature Movement

- Contact closure (Closing the Circuit): Establishing the current path through main contacts.

- Contact separation (Opening the Circuit): Interrupting the power circuit to load.

4. Current Flow and Load Circuit Management

5. De-Energizing the Coil (Magnetic Field)

6. Circuit Interruption (Breaking) Dynamics

7. Cycle Reset

Advanced Performance of GIGAVAC DC Contactors

1. Engineering Design Advantages

1.1. Hermetic Sealing Technology

GIGAVAC‘s hermetically sealed contactors employ advanced containment technologies, utilizing specialized inert gas environments that enhance arc suppression capabilities while preventing environmental contamination. This sealed structure ensures consistent performance across diverse operating conditions.

1.2. Contact System Engineering

The contact assembly incorporates:

- Optimized silver-alloy materials for enhanced conductivity

- Advanced wear-resistant compositions for extended operational life

- Controlled contact pressure systems for reliable operation

1.3. Arc Management Solutions

Arc control system features:

- Advanced magnetic blow-out mechanisms

- Multi-stage arc interruption chambers

- Controlled arc-splitting technology

- Enhanced thermal dissipation design

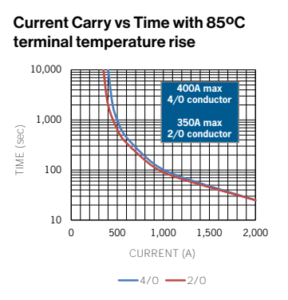

2. Technical Performance Parameters

2.1. Operational Specifications

- Extended voltage range capabilities

- High continuous current ratings

- Superior making and breaking capacity

- Enhanced mechanical endurance characteristics

- Rapid response time metrics

- Minimized contact resistance specifications

2.2. Environmental Resilience

- Broad temperature operation range

- Elevated humidity tolerance

- Advanced altitude performance

- Enhanced vibration resistance

- Comprehensive IP protection ratings

3. Application Versatility

- Electric vehicle power systems

- Renewable energy installations

- Industrial power distribution

- Energy storage systems

- Marine electrical applications

- Railway power management

4. Standards and Certifications

- UL recognition

- CE compliance

- RoHS certification

- ISO quality management standards

- Enhanced safety specifications

5. Long-Term Value Proposition

- Extended service intervals

- Reduced maintenance requirements

- Enhanced system reliability

- Improved safety parameters

- Optimized performance metrics

Applications Guide of GIGAVAC DC Contactors

- Battery disconnect systems

- Main power distribution

- Fast charging infrastructure

- Regenerative braking circuits

- Emergency power shutdown

- Motor controller isolation

- Auxiliary power systems

2. Renewable Energy Solutions

- Solar power installations

- Wind energy systems

- Battery storage units

- Grid-tie inverter systems

- Power conversion equipment

- Energy management systems

- Microgrid applications

- Ground support equipment

- Aircraft electrical systems

- Satellite power management

- Launch vehicle systems

- Test equipment

- Power distribution units

- Emergency systems

4. Marine Applications

- Ship electrical systems

- Submarine power distribution

- Marine propulsion controls

- Battery management systems

- Emergency power systems

- Navigation equipment

- Auxiliary power units

5. Industrial Automation

- Material handling equipment

- Manufacturing process control

- Robotic systems

- Industrial machinery

- Power distribution panels

- Motor control centers

- Safety disconnect systems

6. Energy Storage Systems

- Grid-scale batteries

- UPS systems

- Emergency backup power

- Power conditioning units

- Energy management systems

- Load balancing equipment

- Safety isolation systems

7. Military Applications

- Combat vehicle systems

- Mobile power units

- Communication equipment

- Tactical power systems

- Defense infrastructure

- Emergency shutdown systems

- Field power distribution

8. Railway Systems

- Train power distribution

- Traction control systems

- Auxiliary power supplies

- Battery management

- Emergency disconnection

- Signaling systems

- Platform equipment

Looking for aSolution?

Our Technical Experts are Here to Bring your VISION to Life. Let’s DISCUSS How Our SOLUTIONS Can Maximize the VALUE of your PROJECT

GIGAVAC DC Contactors & Fuses Models

P Series MiniTACTORs

GTM Series Contactors

GX Series Contactors

SGX Series Contactors

MX Series Contactors

GV Series Contactors

HX Series Contactors

Conclusion

GIGAVAC DC Contactors: Engineering Excellence in Power Switching Solutions

INVENTECHS Technology

DC contactors play an important role in electrical systems, providing reliable switching and protection for high-voltage DC applications. Their ability to safely interrupt DC current flow while maintaining circuit integrity makes them indispensable in various industries, from electric vehicles to renewable energy systems.

GIGAVAC‘s comprehensive portfolio of DC contactors exemplifies advanced engineering in power-switching technology, delivering superior performance across demanding applications.

Their hermetically sealed designs, incorporating proprietary arc suppression technology and optimized contact materials, consistently present exceptional reliability in high-voltage DC capabilities up to 1500V, and exceptional current handling capacity position them as a leading choice for demanding applications where safety and dependability are paramount.

As power system requirements continue to evolve, GIGAVAC’s solutions are considered at the forefront of switching solutions manufacturers for the industrial sectors such as electric vehicles, renewable energy systems, and industrial power distribution. This makes GIGAVAC a preferred choice for system designers and engineers seeking high-performance power control components.